Metal dies for extreme durability

No sliding of the stent on the compression mechanism

Can load stents of any length

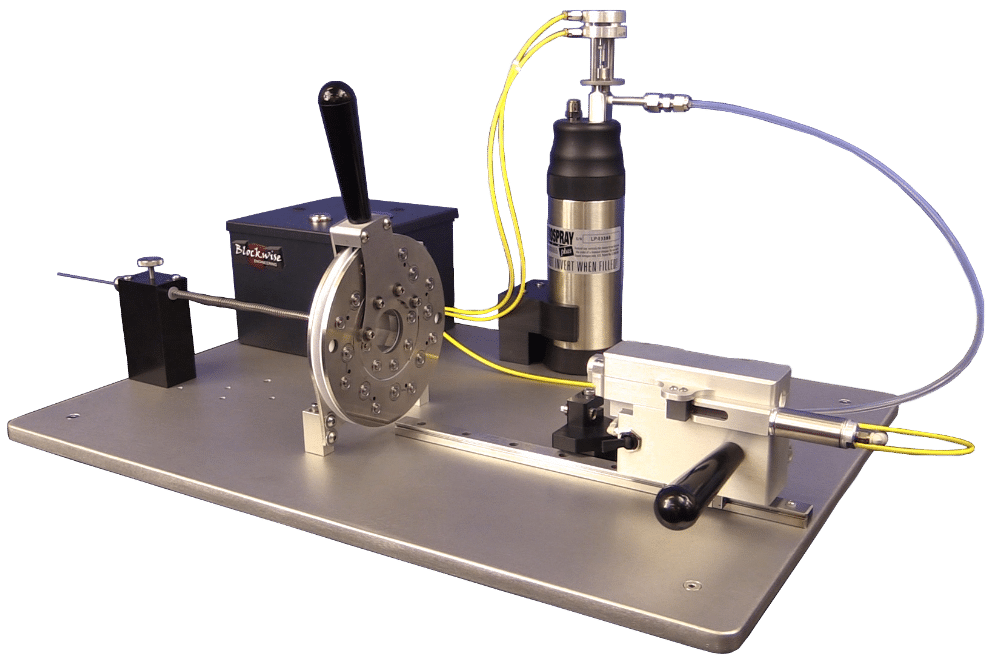

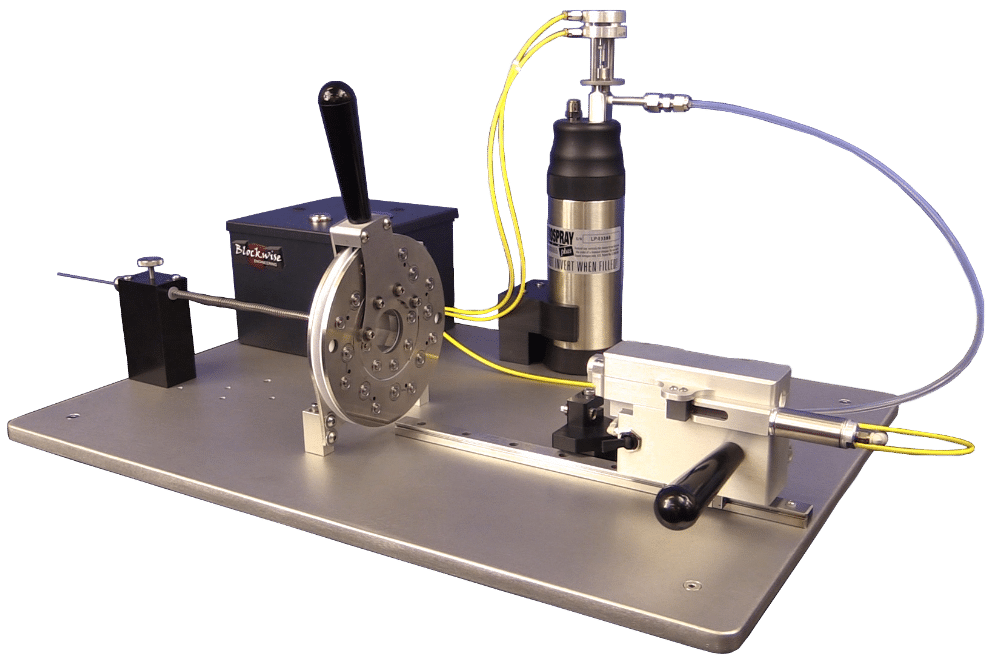

Model NJ Stent Loading Machine

The Catheter Gripper holds the catheter next to the compression opening while the stent is loaded inside. Custom bushings and molded gripper pads keep your product held securely in place.

Liquid Nitrogen cooling allows the stent to be cooled prior to crimping, helping stabilize the stent struts or reducing the radial force of the compression stage.

The Catheter Gripper holds the catheter next to the compression opening while the stent is loaded inside. Custom bushings and molded gripper pads keep your product held securely in place.

Liquid Nitrogen cooling allows the stent to be cooled prior to crimping, helping stabilize the stent struts or reducing the radial force of the compression stage.

| Required Installation Connections – Model NJ | ||||

|---|---|---|---|---|

| Description | Physical Specs | Functional Specs | ||

| Electric Power | Not Required | |||

| Compressed Air | Powers the Gripper, LN2 Valve, etc. (see Knowledge Base: Compressed Air & High Pressure Gas Connections) |

Instant Tube Fitting Accepts ¼-inch OD Plastic Tube | 6.9 to 8.3 bar (100 to 120 psi) |  |

| Liquid Nitrogen | Liquid Nitrogen for cooling bore or catheter | Manual Dewar | None | |

Model NJ with Stent Nozzle™ Compression Station

The tapered entry of the Stent Nozzle™ allows for processing any length of stent. Ball bearings between all moving surfaces means low friction and virtually infinite life. Short length permits more access than any other stent loader.

| Diameter | Straight Length | Tapered Length | Max Radial Force | Die Material |

|---|---|---|---|---|

| 0-30 mm | 6.35 mm | 25.4 mm | ~530 N | Hardened Stainless Steel |